Company news

Managing the risk of cracking of heat treatment fixtures during quenching

The temperature of heat treatment #fixtures

drops dramatically during quenching, especially in the case of water cooling.

How to avoid cracking of heat treatment fixtures during quenching?

Our experts have gained sufficient experience from design to production.

✅First, significant wall thickness differences will be avoided,

especially in the joint area. Stress relief location is also taken into

account.

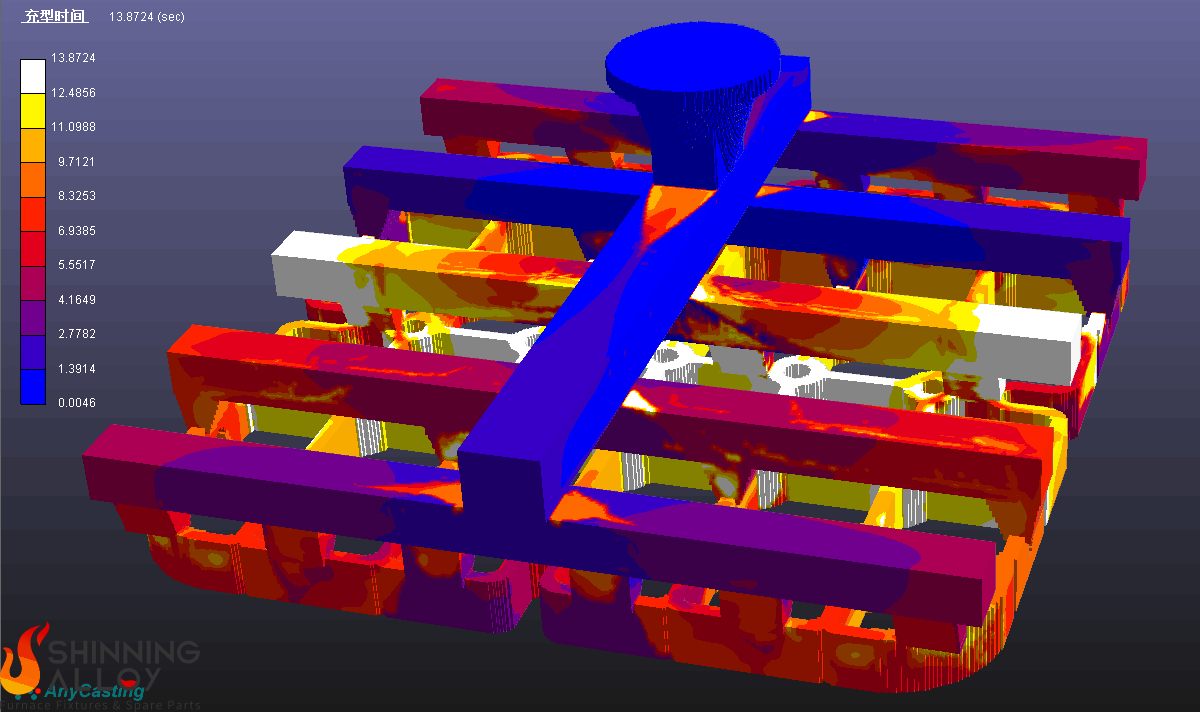

✅Then, sufficient and appropriate feeder and running system is

considered in the production of the wax pattern to guide the molten steel to

each corner of the castings and avoid internal shrinkage.

At some condition, feeder and running

system can reach to 80%-90%.

✅Finally, no scrapped steel is used during the metal melting

process to minimize the material impurities and ensure the material purity.

At Shinning Alloy, we guarantee the longer life of our heat treatment fixtures

through multiple control in each production process.

Do you want to improve the performance of

your #Baskets, #Trays and Charging Fixtures? Consult with our expert.